Small body, big energy, take you into the world of micro motor

Do not look at the miniature motor so small, its small body but contains a lot of energy Oh! Micro motor manufacturing processes, involving precision machinery, fine chemicals, microfabrication, magnetic material processing, winding manufacturing, insulation processing and other process technologies, the number of process equipment required is large, high precision, some micro motors may have a higher technical content than ordinary motors.

According to the height of the base foot plane to the center of the shaft, motors are mainly divided into large motors, small and medium-sized motors and micro motors, of which, motors with a center height of 15mm-71mm are micro motors. This is the most basic feature to identify the micro motor, next, let's look at the definition of micro motor in the encyclopedia.

"Micro motor (full name miniature special motor, referred to as micro motor) is a kind of volume, capacity is small, the output power is generally below a few hundred watts, the use, performance and environmental conditions require a special class of motor. It refers to the motor with diameter less than 160mm or rated power less than 750W. Micro motors are often used in control systems or transmission mechanical loads for the detection, analysis operation, amplification, execution or conversion of electromechanical signals or energy, or for transmission mechanical loads, and can also be used as AC and DC power supplies for equipment. Such as disk drives, copiers, CNC machine tools, robots, etc. have applied micro motors."

From the working principle, the micro motor is converted into mechanical energy through electrical energy. The rotor of the micro motor is driven by the current, the different rotor current direction produces different magnetic poles, resulting in interaction and rotation, the rotor rotates to a certain angle, through the commutator's commutation function can take the current direction to change the rotor magnetic polarity change, keep the rotor and stator interaction direction unchanged, so that the micro motor began to rotate non-stop.

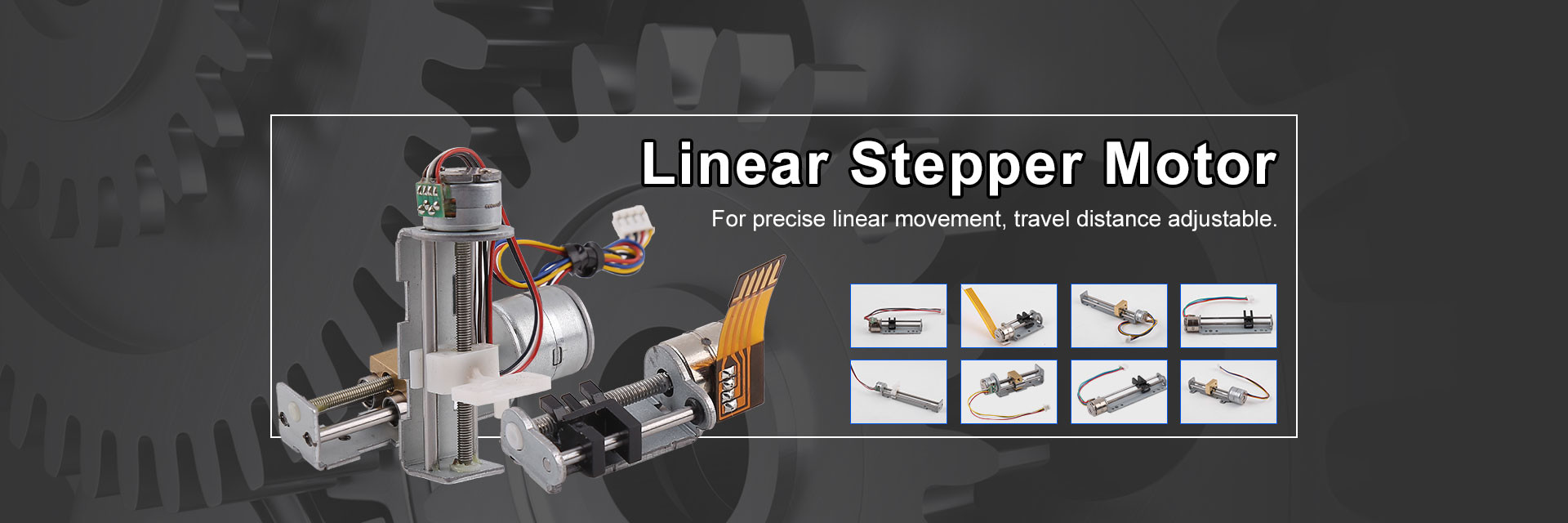

In terms of the types of micro motors, micro motors are divided into three main categories: drive micro motors, control micro motors and power micro motors. Among them, the driving micro motors include micro asynchronous motors, micro synchronous motors, micro AC commutator motors, micro DC motors, etc.; the control micro motors include self-tuning angle machines, rotary transformers, AC and DC speed generators, AC and DC servo motors, stepper motors, torque motors, etc.; the power micro motors include micro electric generator sets and single armature AC machines, etc.

From the characteristics of micro motors, micro motors have the advantages of high torque, low noise, small size, light weight, easy to use, constant speed operation, etc. They can also be matched with a variety of gearboxes to achieve the purpose of changing the output speed and torque. The miniaturization of motors brings unprecedented benefits to manufacturing and assembly, such as the possibility of using special materials that were difficult to consider for large-size motors due to cost and other factors - film, block and other shaped structure materials are easy to prepare and obtain, etc.

With the advancement of intelligence, automation and information technology in various fields of production and life, there are many varieties of miniature motors, complicated specifications, and a wide range of market applications, involving the national economy, national defense equipment, all aspects of human life, industrial automation, office automation, home automation, weapons and equipment automation is essential for the key basic mechanical and electrical components, where the need for electric drive can be See the micro motor.

① Electronic information equipment field, mainly concentrated in cell phones, tablet PCs and wearable information devices. For the thin electronic products, the matching micro motor has a certain demand on the size, so the emergence of the chip motor, the smaller chip motor is only the size of a coin, micro motor in the drone market is also widely used;

②In the field of industrial control, with the development of industrial automation, micro motors have made a great contribution to industrial control. There are robot arm, textile equipment and valve position system, etc.

③In the field of home appliances and tools, micro motors for home appliances present a wider range of uses. There are monitoring equipment, air conditioners, intelligent home systems, hair dryers and electric shavers, electric toothbrushes, home health care equipment, electronic locks, tools, etc.;

④In the field of office automation, digital technology is advancing and the use of various electronic machines in the network is increasingly required to be uniform, and micro motors are assembled in printers, copiers, vending machines and other equipment;

⑤ In the medical field, micro-trauma endoscopy, precision microsurgical machinery and micro-robots require highly flexible, highly dexterous and highly flexible ultra-miniature motors that are small in size and large in power. Micro motors are mainly used in medical treatment/examination/testing/analysis equipment, etc..

⑥ In audio-visual equipment, in cassette recorders, the micro-motor is both a key component of the drum assembly and an important element in the drive of its leading axis and the automatic loading of the cassette as well as the control of the tape tension;

⑦ In electric toys, micro DC motors are usually used. The load speed of the micro motor determines the speed of the toy car, so the micro motor is the key for the toy car to run fast.

Micro-motor integrated with the motor, microelectronics, power electronics, computers, automatic control, precision machinery, new materials and other disciplines of high-tech industries. With the development of science and technology and electrical control systems continue to update, the requirements of various industries for micro-motors are increasingly high, at the same time, the application of new technologies, new materials, new processes, promote the development of micro-motors, especially the application of electronic technology and new materials technology is driving the continuous progress of micro-motor technology. Micro-motor industry has become an indispensable basic product industry in the national economy and national defense modernization.

Micro motors occupy an unshakable position in the field of automation, such as the key means of applying automation technology in the logistics chain is the use of high-performance micro motors. In the field of UAV, as the micro DC brushless motor is the most important component of micro and small UAV, its performance is directly related to the good or bad flight performance of UAV. So with high reliability, high performance and long life brushless motor market for drones is taking off, it can be said that drones have become the premise of the next blue ocean of micro motor. In the future, along with the traditional application market is increasingly saturated, micro motor will be in new energy vehicles, wearable devices, drones, robotics, automation systems, smart home and other emerging areas of rapid development.

Ltd. is a professional research and production organization focusing on motor research and development, overall solutions for motor applications, and processing and production of motor products. Changzhou Vic-tech Motor Technology Co., Ltd. has been specialized in manufacturing micro motors and accessories since 2011. Our main products: miniature stepper motors, gear motors, underwater thrusters and motor drivers and controllers.

Our team has over 20 years of experience in designing, developing and manufacturing micro-motors for special needs product development and auxiliary design customers! At present, we mainly sell to customers in hundreds of countries in Asia, North America and Europe, such as USA, UK, Korea, Germany, Canada, Spain, etc. Our "integrity and reliability, quality-oriented" business philosophy, "customer first" value norms advocate performance-oriented innovation, collaboration, efficient spirit of enterprise, to establish a "build and share "The ultimate goal is to create maximum value for our customers.

We interact closely with our customers, listening to their needs and acting on their requests. We believe that the basis of a win-win partnership is product quality and customer service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!