Our company has a professional engineer team with 20 years of experience in the industry. We can develop products according to the needs of customers, and can also develop products in collaboration with the customer engineer team. In this way, customers can avoid improper selection of motors or inappropriate costs in the early stage of product development. At the same time, in the early stage of development, the production feasibility and production convenience of the product were considered to the greatest extent, so the follow-up laid a good foundation for providing customers with high-quality and low-cost products.

For the smooth development of customers and our business, please refer to the flow chart below, cooperate with us, and carry out the development of new products in an orderly manner in stages and steps.

STEP 1:

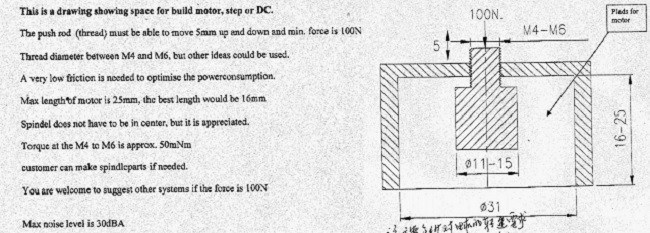

At this stage, customers can provide information such as product design ideas and instructions for use according to their needed

. such as the basic action requirements, basic strength requirements, and basic space requirements for the motor.

It can be provided by email description, preliminary drawings, illustration pictures, related videos, animation demonstrations, etc.

If necessary, video conference demonstrations can be provided to us, so as to let us know the needs of customers to the greatest extent, which will help the successful development of the project. a solid foundation.

STEP 2:

According to the communication and communication in the first step, please provide conceptual design sketches, 3D drawings, or descriptions of important indicators and requirements of the project.

Our company designs preliminary drawings according to these requirements. Generally speaking, we will use the current standard products as the reference benchmark. This will greatly reduce the cost of post-production after design.

STEP 3:

On the basis of the previous communication, the customer and us will initially come to the preliminary design of the scheme,.

Then the scheme will finally form technical documents such as drawings.

The customer reconfirms whether the parameters such as space and strength are satisfied from the perspective of use.

We will confirm the feasibility of production, cost feasibility, etc. from the perspective of product production.

This can ensure that the product can meet the requirements from production to use.

STEP 4:

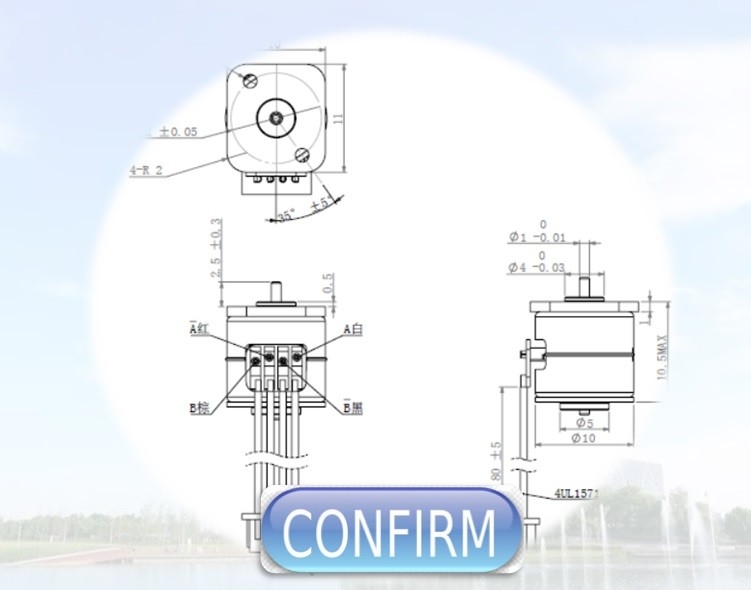

Confirmed preliminary plans and sketches. At this stage, complete 3D drawings, 2D drawing and other formal documents should be produced.

These documents need to be confirmed and signed by both parties. Follow-up work will be carried out in accordance with these confirmed drawings and documents to avoid objections and follow-up changes.

When some needed changing occurs, corresponding changes and confirmations must be made in the drawings and other documents.

STEP 5:

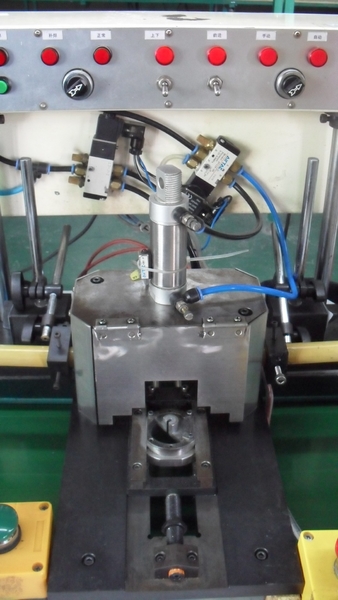

According to the approved information and data, various feasible methods are used for processing different parts.

According to the necessity of assembly, make temporary available simple jig, and then carry out assembly and test, the assembly test meets the design requirements and submit the product to the customer for further testing, certification, etc.

STEP 6:

After the samples are produced and tested by our company, the samples that meet the preliminary design requirements will be provided to customers for assembly and testing.

At the same time, our company retains some samples, and after the customer's test is completed, according to the customer's test results, it is convenient to carry out necessary testing, analysis and improvement confirmation.

STEP 7:

After the sample test passes the customer's inspection, the relevant design for mass production can be carried out, including two-piece design, assembly process design, failure mode analysis, tooling design, special equipment design and production, mold design and production, etc.

STEP 8:

Before mass production, we will inspect and approve the parts that open the mold, verify the newly produced fixtures, and accept the newly designed and produced equipment.

Then, samples are submitted for final confirmation before mass production, followed by 1-2 small batch trial production, and finally enter the mass production stage.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!